JOB: Lemon Wedging and Traying System

Description:

Hi-Standard proposes to provide one (1) Single station wedging and traying system for lemons consisting of:

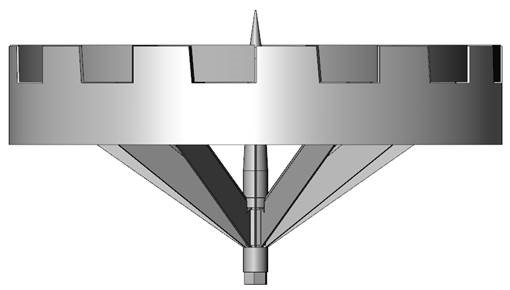

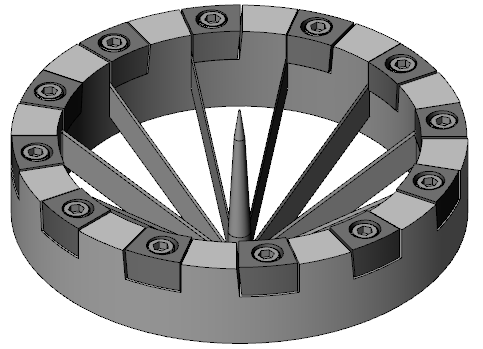

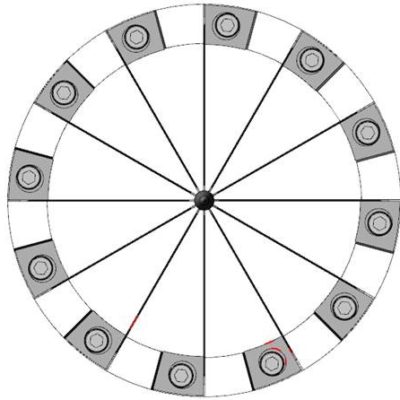

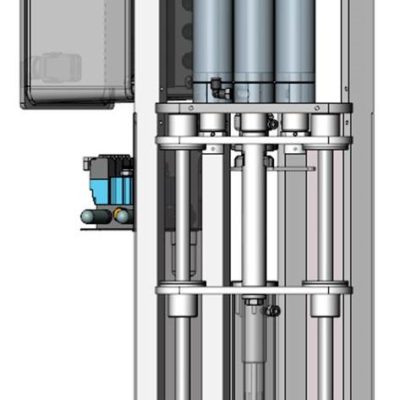

PASS Model V- Citrus Slicing Machine

12 Blade 7/8 Dia. Coring -Standard (coring can be turned off for lemons)

Configuration for Citrus

- 12 Blade needle cassette for all citrus

- Crating/Shipping/Installation/Training (for PASS System)

(ships from Seattle, WA)

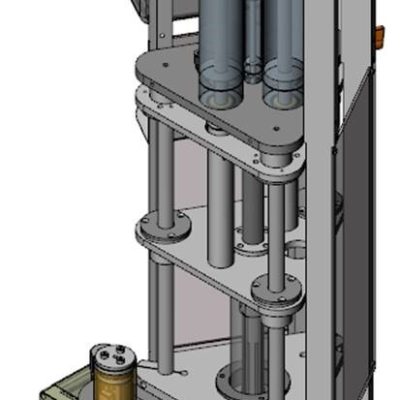

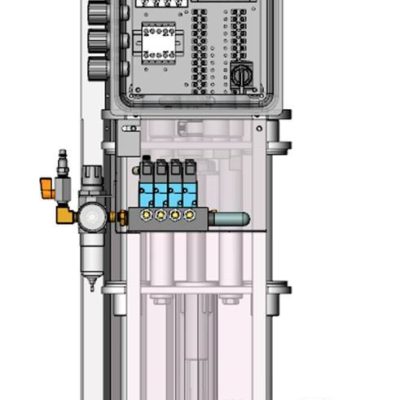

Traying Conveyor/Wash System

- Circulating wash tank to present Lemons to Operator

- Doran 7000XL Scale for Tray Filling (1 station/500lb per hour Max capacity)

- 12” X 90” Conveyor to convey filled Trays to Sealer/Rack

- Shelf for Empty Tray Storage

Operation:

Two (2) operators, 1 Replenishing lemons in wash tank and 1 operating PASS Model V.

PASS operator takes lemons from wash tank directly in front of them. When loading the PASS machine, the cycle is automatically triggered when the operator removes their hand from the loading zone. No buttons to push

The Pass machine surgically slices the lemon directly into the tray, which is sitting on the Doran 7000 scale. When the target weight is acquired the operator pushes the full tray onto the conveyor for transport to sealer/rack.

Additional Features

- Blade cassettes are easily removeable

- Individual blades can be replaced without replacing the entire cassette

- This machine is also be able to core and

slice all other soft-cored fruits (apples, pears, oranges, grapefruit, kiwi, etc.). With the proper cassettes

- The wash and traying system is expandable to two (2) positions. (increasing capacity to 1,000lbs/hour

- A separate treatment system can be added for slicing apples

Click here for more information or to get a quote